Precision Components. Accurate to the Ultimate

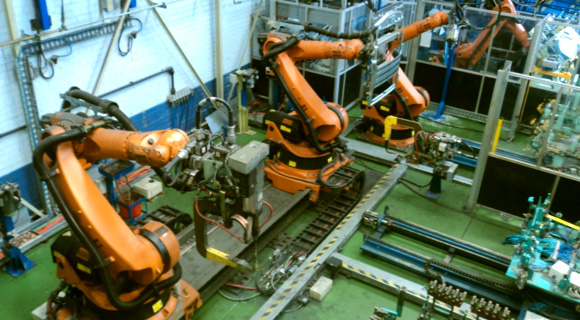

Robotics Operations

Precision Components uses state-of-the-art robotic technology to ensure the highest levels of precision and consistency.

Programmed automation is most commonly employed in the areas of MIG and spot welding, weld sealant and projection welding applications.

MIG welding robotic cells

- 20kg Fanuc with Lincoln mig welding equipment and servo-driven rotary fixture ends

- 2 x 15kg Fanuc dual robot mig welding cell and servo-driven rotary fixture ends

Spot Welding Robotic Cells

3 x Spot Welding Kuka Robots:

- Obara 500kg C-Type servo weld guns

- Dual linear and rotating servo-driven fixture shuttles

- Automatic tip dressing and changing

1 x Spot Welding Robotic Cell:

- Obara 500kg C-Type servo weld guns

- Dual linear and rotating servo-driven fixture shuttles

- Automatic tip dressing and changing

- Automatic weld sealant and anti-flutter application

- Obara automatic stud and nut welding capabilities

35 Axis Robotic Assembly Cell:

- 2 x 240kg Kuka Robots

- 2 x 150kg Kuka Robots

- 2 x Obara 500kg C-Type servo weld guns

- 1 x Obara 500kg X-Type servo weld gun

- 4 x servo-driven linear and rotating fixture shuttles

- 1 x 4m Kuka servo-driven linear track

- 2 x automatic tip dressing and changing

- 2 x Obara drawn arc stud welding stations

- Automatic weld sealant and anti-flutter application

- Robotic tool changing capability

Other assembly equipment:

- Four large, flexible overhead manual welding cells using a variety of modern guns, controllers and transformers

- Heavy-duty pedestal welders all with electronic controllers

- Dispensers to apply glues, sealants and anti-flutter compounds

Talk to us today to find out more.